Turning CO₂ into Assets with Microalgae Carbon Capture, Utilization & Storage (CCUS)

Transforming urban infrastructure into carbon sinks with nature-based biotechnology solutions

Turning CO₂ into Assets with Microalgae Carbon Capture, Utilization & Storage (CCUS)

Transforming urban infrastructure into carbon sinks with nature-based biotechnology solutions

Turning CO2 Into Assets With Intelligent Carbon Capture

Carbelim combines biotechnology and nature to drive a climate-positive future for urban environments worldwide. We deploy innovative microalgae-based biomimetic facade systems and intelligent photobioreactors that actively capture CO2, eliminate pollutants, and produce valuable biochar and carbon credits—delivering net-zero carbon solutions for cities where traditional tree planting isn’t feasible.

Our climate tech platform merges cutting-edge biotechnology with nature-inspired innovation, creating scalable solutions that convert emissions into sustainable resources. Through advanced microalgae cultivation systems, we transform pollution into biochar, clean air, and verified carbon credits, enabling a truly circular carbon economy.

Supported by global accelerators and leading research institutions, Carbelim scales science-driven solutions to build healthier, climate-resilient cities. We are committed to carbon footprint reduction through climate-positive innovation that benefits businesses, communities, and the planet.

Transforming Emissions Into Resources - Efficiency per m²

Per m² annually by our biomimetic facades

Fine particulates filtered from urban air

Microalgae carbon fixation efficiency

Our mission is to convert emissions into sustainable resources—transforming pollution into biochar, clean air, and carbon credits for a net-zero carbon economy. Each deployment demonstrates measurable environmental impact through live IoT-enabled CO2 and air-quality analytics, providing real-time verification of carbon sequestration and urban air purification results.

Urban Air Purification Results

These results highlight Carbelim’s efficacy in cleaning city air and providing carbon sink solutions on-site. Our installations actively generate fresh oxygen and visibly improve Air Quality Index (AQI) in deployment zones, making a measurable step toward net-zero carbon solutions for metropolitan areas.

from urban environments

at deployment sites

in monitored zones

Live monitoring capabilities: IoT-enabled CO2 and air-quality analytics provide real-time monitoring and verification of environmental impact across all deployment zones, ensuring transparency and accountability in carbon capture performance.

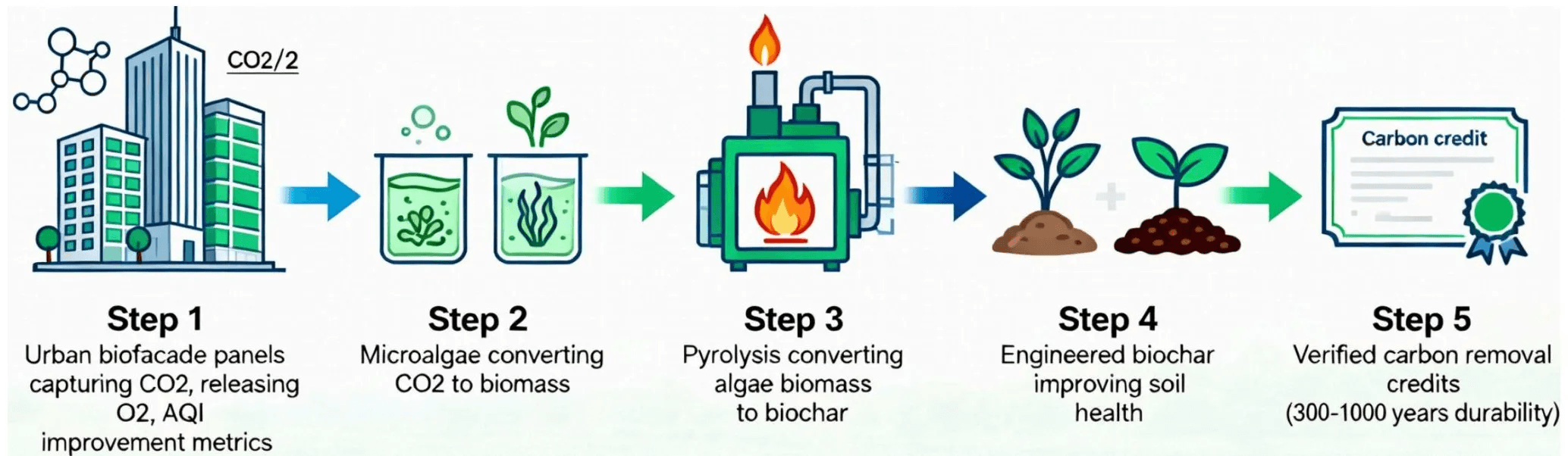

How It Works: End-to-End Carbon Removal

Carbelim has developed an integrated, end-to-end carbon removal pathway that begins with urban CO2 capture and culminates in permanent, soil-enriching biochar. Our system combines biomimetic architecture, regional waste valorization, and advanced pyrolysis to deliver verified, high-integrity Carbon Dioxide Removal (CDR) credits.

This approach addresses multiple sustainability challenges simultaneously: improving urban air quality, sequestering atmospheric carbon for centuries, regenerating degraded soils, and creating economic value from waste streams. Each stage of our process is measurable, verifiable, and designed for scale.

The Carbon Removal Pathway

Our comprehensive six-step process transforms urban CO2 emissions into permanent carbon sequestration, creating verified carbon removal credits while improving city air quality and soil health.

01

Urban CO2 Capture

Biomimetic facades remove pollutants at source or direct, actively filtering urban air

02

Algal Biomass Production

Nutrient-rich microalgae cultivation through optimized photosynthesis

03

Waste Stream Integration

Blending with regional agri/organic residues for maximum efficiency

04

Advanced Mobile Pyrolysis

High-temperature conversion to stable carbelim engineered biochar

05

Permanent Sequestration

Century-scale carbon storage delivery to soil systems

05

Premium CDR Credits

Verified, high-integrity carbon removal for global markets

Step 1: Capture CO2 From Urban Atmosphere

Carbelim’s Biomimetic Facade (CBF™) systems actively remove urban CO2 and airborne pollutants, improving local air quality while generating real-time environmental data. These living walls integrate seamlessly into building architecture, transforming static structures into dynamic carbon capture systems that operate at the point of emission.

Vertical Flat Photobioreactors

Each facade module circulates microalgae cultures that absorb CO2 through photosynthesis, functioning as living carbon capture units

24/7 Air Purification

The system operates continuously, providing round-the-clock air purification and carbon sequestration regardless of time or weather

Architectural Integration

Seamless design compatibility allows installation on existing buildings without structural modifications

Steps 2-3: Biomass Production and Waste Integration

Step 2: Produce High-Value Algal Biomass

As CBF™ panels capture CO2, they cultivate nutrient-rich microalgae biomass—a valuable feedstock for carbon removal and soil regeneration pathways. The microalgae grow rapidly, fixing carbon up to 400× faster per unit area than mature trees.

This biomass represents captured atmospheric carbon in biological form, ready for conversion into permanent storage solutions. The cultivation process is optimized through AI-driven controls that monitor growth conditions and maximize carbon uptake efficiency.

Step 3: Integrate Regional Waste Streams

This algal biomass is blended with regional on-site agricultural, forestry, and organic residues, creating a sustainable feedstock for engineered biochar production. By integrating regional waste streams, we maximize resource efficiency and create value from materials that would otherwise decompose and release CO2.

This approach transforms multiple waste streams into a unified carbon removal solution, addressing both urban emissions and agricultural waste management simultaneously while reducing transportation costs and environmental impact.

Steps 4-5: Pyrolysis and Permanent Storage

Step 4: Advanced Pyrolysis

The blended material undergoes high-temperature pyrolysis, producing microalgae-enhanced, recalcitrant biochar designed for century-scale carbon stability. This thermochemical process occurs in the absence of oxygen, preventing combustion and ensuring maximum carbon retention.

- Temperature Control: Precise heating ensures optimal carbon structure and stability

- Quality Assurance: Each batch tested for carbon content and permanence

- Energy Recovery: Process heat captured for system efficiency

Step 5: Permanent Sequestration

The resulting biochar is optimized for long-duration carbon sequestration, soil revitalization, and regenerative land management. When applied to soil, biochar remains stable for centuries, effectively removing CO2 from the atmosphere permanently.

Beyond carbon storage, biochar improves soil water retention, enhances nutrient availability, and supports microbial ecosystems. This creates a regenerative cycle where carbon removal directly benefits agricultural productivity and ecosystem health.

Step 6: Generate Premium CDR Credits

Under rigorous MRV (Monitoring, Reporting & Verification) protocols, each ton of biochar delivers approximately 2.6 tons of verified CO2 removal, enabling high-integrity, premium Carbon Dioxide Removal (CDR) credits for global carbon markets. Our credits are verified under internationally recognized standards including Verra VM0044 and Puro.earth, ensuring transparency, permanence, and credibility.

2.6 Tons CO2

Removed per ton of biochar produced

100% Verified

Third-party audited and certified

Every credit is traceable from capture through conversion to permanent storage, with zero-mile logistics minimizing transportation emissions. Our comprehensive verification process ensures that businesses and investors can confidently offset their carbon footprint while supporting urban air purification and soil regeneration initiatives.

Our Supporters

Carbelim collaborates with global partners across engineering, biotechnology, real estate, urban governance and industrial decarbonisation.

FAQ'S

How much CO₂ can a Carbelim photobioreactor remove?

Our systems typically remove 1–1.5 kg of CO₂ per m² per day depending on climate, reactor type and placement.

Do the systems work indoors & outdoors?

Yes — we provide HVAC-integrated indoor units and outdoor modules for facades, towers and transit shelters.

Is the biomass usable or waste?

Biomass is a valuable CCU output used for omega-3 oils, proteins, pigments and biopolymers — not waste.

What are the power requirements?

Module auxiliary power is typically 12–20W. Solar can be used for partial or full energy supply in some deployments.

Can Carbelim integrate with BMS?

Yes — our IoT stack exports telemetry and health metrics to BMS, dashboards and ESG platforms.